Catalogues – Air torque

Catalogues

- AGA Approval

- Company product overview

- Upgrade Series Compact R&P Actuator

- AT-HD Series Scotch Yoke Pneumatic & Hydraulic Actuator Catalogue

- AT-HD Series Scotch Yoke Pneumatic & Hydraulic Actuator- Torques & Dimensions

- AT-HDC Compact Series Scotch Yoke Pneumatic Actuator Catalogue

- AT-HDC Compact Series Scotch Yoke Pneumatic Actuator Data Sheets

- S Series 316 SS Actuator

- AT 120° 135° 180° DA Actuator

- AT 180° Spring Return Actuator

- AT 90º Three Position Actuator

- AT 180° SR Actuators 90° Fail Safe

- Top Smart Position Monitor

- AT Overview Control Systems

- Electric Actuators

Data Sheets

- Pneumatic Actuator c/w Hydraulic Dampner/Speed Controller

- Water Operated Actuator

- Multi Function Indicator – Limit Switch

- Fast Acting Upgrade AT Series

- M.A.C. Multi-Actuation AT Series

- Actuator Safety Lock-out System

- S Series 316 SS Actuator

Certification – Compact R&P AT-Upgrade

- Atex Certificate

- ISO 9001 Certificate

- SIL3 Certificate AT/PT

- DNV Certificate

- EU Declaration of Conformity 4THG Upgrade Series

- EU Declaration of Conformity Stainless Steel (SB-AT) Series

- Corrosion Salt Spray Test

- IP67 4TH GU Series Enclosure Certificate

- IP67 SS (SB-AT) Series Enclosure Certificate

- IP68M-4TH GU Series Enclosure Certificate

- IP68M-SS (SB-AT) Series Enclosure Certificate

MANUALS – Compact R&P AT-Upgrade

- I.O.M. Manual AT045U-AT801U

- I.O.M. Manual AT1001U-PT1000U

- SIL Safety Manual AT Series

- SIL Safety Manual SS Series

- ATEX R&P (4TH G&S (SB-AT) Safety Instructions

Certification – Scotch Yoke AT HD & ATHDC

- Atex Certificate AT-HD

- Atex Certificate AT-HDC

- SIL3 Certificate AT-HD

- SIL3 Certificate AT-HDC

- EU CED PED Certificate AT-HD

- EU CED PED Certificate AT-HDC

MANUALS – Scotch Yoke AT HD & ATHDC

Air Torque – Italy, design and manufacture a range of SIL3 and Atex Ex (for explosive atmospheres) certified pneumatic rack & pinion AT Series actuators in aluminium and stainless steel. Air Torque actuators operate on pressures of up to 8 bar as standard. The actuators can be operated with air or inert gas and are Atex certified for explosive atmospheres. Air Torque actuators are continuously on test, they have been tested to 4 million cycles! Global Supply Line are sole regional agents for Air Torque. To view our stock list of Air Torque AT Series actuators click here.

A wide range is available in both double acting and spring return delivering torques up to 11,000 Nm. Eighteen models provide a highly economical sizing selection. As well as conventional quarter turn actuators, Air Torque also offers actuators for special applications such as: forged stainless steel actuators, 120, 135 degree and 180 degree double acting actuators, 180 degree spring return, and 180 degree spring return with 90 degree fail safety position, as well as fast acting actuators. Water or bio-oil can also be used to drive the AT series if ordered with correct trim (see separate brochure for water trim).

The 4th generation patented upgrade AT series permits greater product versatility for easier and reliable valve automation. Air Torque’s design is easier to maintain than other brands. The AT Series is also sold in North America as the PT series for marketing and licensing reasons only. GSL maintains substantial Air Torque inventories in our Adelaide warehouse. A full 24 month warranty is provided. Click here to view our stocks of Air Torque actuators, brackets and adaptors, etc. Our valve automation centre can size, fit and test all types of actuated valve packages. Global Supply Line Engineering are the sole approved Air Torque service, repair and automation facility. Click here to view approvals

- Click here for Airtorque Actuation Sizing Software

- Click here for Heavy Duty Compact Actuators for Oil & Gas Industry

PED 97/23/EC. ATEX 94/9/EC. SIL3 IEC 61508. GOST-R. DNV type approval.

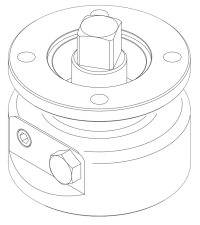

Scotch Yoke HD Series

ACTUATED VALVE – ONE SOURCE

Starline Spa and Air Torque Spa are situated in the one facility. The world’s largest compact actuator manufacturer and the world’s premier forged floating & trunnion ball valve manufacturer and in the same Bergamo manufacturing site, one of the most modern in the world. For turnkey supply of actuated valve packages a single source solution provides assurance of compatibility and quality as well as competitive, reliable delivery times.

In accordance with stringent European requirements, Air Torque actuators are under a continuously automatic cycle test programme to ensure efficiency. Air Torque actuators and all parts are 100% western European made and exclusively manufactured in Italy. 4th generation Airtorque actuators have external travel stops for open and close position adjustable from -5° to +15° and from +75° to +95°. This special feature eliminates alignment problems due to a clearance of connections between the stem of the valve adaptor and the shaft of the actuator. A triple piston bearing system provides Airtorque actuators with a constant torque, even under high loads. In addition to the guides on the outside of the piston there is an additional guide inside which absorbs the cross load through the integrated support at the drive shaft. Other available options include gear over-rides and hydraulic dampners.

BLOCK AND SAFETY LOCK-OUT SYSTEM PARTIAL STROKE SYSTEM BLOCK TO SUIT AIR TORQUE QUARTER TURN RACK & PINION PNEUMATIC ACTUATOR

The BS-LS locks the valve in open or close position (as a safety, when for example service is done, not to accidentally activate the valve).

The BS-PS locks the valve in a small range of movement (i.e., allows it to move a certain degree). By limiting this range, allowing partial stroke test of actuator, one can for example check that the valve is not stuck and still functions.

For information on AT801 and AT1001 Heavy Duty High Torque Compact Actuators

click here

click here

The drive shaft is held in position by two bearings, one at the top of the pinion, one at the bottom. This ensures less friction and abrasion-free operation. Due to the special design of the bearings at the shoulders of the piston, the drive shaft is blowout proof and fulfills the stringent US standards for product liability. The drive shaft has a 25-30 µm electroless nickel coating (Protection E – Stainless steel). The bearings are temperature resistant to 155°C. Due to an internal retaining shoulder the bearings are blowout safe.

Maintenance free spring cartridges allow a safe and simple assembly and disassembly. Therefore the adaptation of the AT actuators to your working conditions with the recommended pneumatic pressure can be arranged easily.

Serial inspection: Each actuator has to pass a comprehensive serial inspection with e.g. a tightness / density check and a torque check. After passing the inspection the actuator is given a serial number according to ISO 9001.

‘S’ series Full 316 SS – Click here

‘TOP SMART’ intelligent position monitor:

Air Torque also manufacture the ‘Top smart’ intrinsically safe compact valve position monitor with integrated diagnostics, self calibrating limit switches, integrated solenoid valve and air lines as well as practical stroke testing and contactless position sensing (can be fully integrated with intelligent safety plant instrument systems).

This unit has smart functions like rotary motion counter, temperature indication and operating hours counter as well as solenoid valve status LED. Download brochure above at this web page.

4th Generation AT Actuator

The advantages

INCREASED EXTERNAL STROKE ADJUSTMENT

The stroke adjustment in the OPEN and CLOSE position has been increased to 20° which provides an exact adjustment for a precise stroke.

The stroke adjustment in the OPEN and CLOSE position has been increased to 20° which provides an exact adjustment for a precise stroke.

FLAT END CAP DESIGN

Our new end cap design allows easier maintenance and service through a flat cover shape.

Our new end cap design allows easier maintenance and service through a flat cover shape.

IMPROVED VISUALISATION

The accurate scaling allows a precise visualisation of the stroke range with-out further accessories.

The accurate scaling allows a precise visualisation of the stroke range with-out further accessories.

SPRING CARTRIDGE

• Service-friendly safety springs

• Number of springs variable according to supply pressure

• Corrosion protected

IMPROVED POSITION INDICATOR

A long-lasting connection requires components on eye-to-eye level, i.e. transferred to the position indicator, a solid stainless steel coupling for synchronisation with the sensor.

FLEXIBILITY FOR MOUNTING

AIR TORQUE actuators offer a wide range of square & star connections. This in combination with ‘square reductions’ enables a flexible adaption for almost every application.

TEMPERATURE RANGE

The temperature range of our standard actuators has been increased to -40°C with new and improved sealing materials. Almost all European locations can now be served with our standard actuators even during winter time.

The temperature range of our standard actuators has been increased to -40°C with new and improved sealing materials. Almost all European locations can now be served with our standard actuators even during winter time.

View our Airtorque Actuator and Spare Parts Stock List

AT801SR Actuator

AT801SR Actuator